The Introduction of Rock Bolts Application and Types

Time:2024-07-11From:sinorock View:

Rock bolts are a fundamental element in underground construction and geotechnical engineering, widely used for supporting tunnels, caverns, and high slope stabilization projects. The primary function of rock bolts is to stabilize rock masses by anchoring and reinforcing the rock, preventing collapses and ensuring the structural integrity of underground spaces. This article delves into the various types of rock bolts, with a particular emphasis on self-drilling rock bolts, their applications, construction methods, and the latest advancements in the industry.

Overview of Rock Bolts and Their Applications

Rock bolts are essential in underground construction and slope stabilization, providing a method to transfer load from the unstable rock to the stable rock mass. The applications of rock bolts are diverse and critical in projects such as:

- Underground Caverns: Providing stability and preventing collapses in large underground spaces.

- Tunnel Support: Ensuring the integrity of tunnel walls and ceilings during and after excavation.

- High Slope Treatment: Stabilizing slopes to prevent landslides and erosion.

The primary materials used for rock bolt binding include cement mortar, chemical anchoring agents, resin, or mechanical methods to secure the bolts within drilled holes.

Types of Rock Bolts

Rock bolts can be classified based on the type of anchoring agent used and the method of applying anchoring force. Here, we explore the major types of rock bolts:

Full Length Bonded Rock Bolts

Full length bonded rock bolts involve a rock bolt rod that is entirely in contact with the bonding material once injected into the drilled hole. This type of bolt offers strong anchoring force due to the continuous bond along the entire length of the rod.

Prestressed Rock Bolts

Prestressed rock bolts apply an anchoring force to the rock mass structure before any deformation occurs. This pre-tensioning effectively stabilizes unstable rock structures, providing immediate support and reducing the likelihood of rock displacement.

Friction Rock Bolts

Friction rock bolts are anchored by the frictional resistance between the rock bolt rod and the hole wall. This type of bolt relies on the immediate mechanical interlock to provide stabilization, often used in dynamic environments where quick installation is required.

Mortar Rock Bolts

Mortar rock bolts use cement mortar or fast-hardening cement mortar as the anchoring agent. The mortar provides a robust bond between the bolt and the surrounding rock, ensuring long-term stability and load transfer.

Cement Coil Rock Bolts

Cement coil rock bolts use cement rolls as the anchoring agent. This method involves placing a coiled cement paste within the drilled hole, which then hardens to secure the rock bolt.

Resin Rock Bolts

Resin rock bolts employ resin as the anchoring agent. Resin provides a strong, quick-setting bond, making these bolts suitable for environments requiring rapid stabilization. However, they are generally more expensive due to the cost of the resin.

Classification by Construction Method

The construction method used for installing rock bolts significantly impacts their performance and suitability for different applications. Here are some common methods:

Self-Drilling Rock Bolts

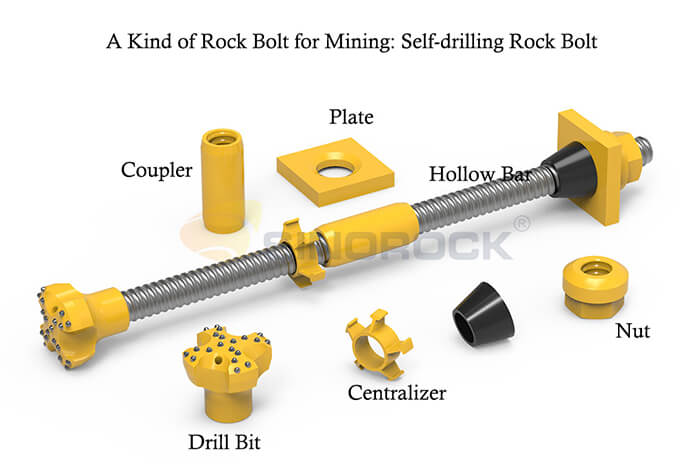

Self-drilling rock bolts are a comprehensive solution, integrating drilling, grouting, and anchoring into a single operation. Comprising a hollow bar rod, nut, plate, coupler, centralizer, and drill bit, these bolts are ideal for various applications including slope support, foundation pit support, tunnel pipe shed support, and more.

Advantages of Self-Drilling Rock Bolts:

- High Construction Efficiency: Combining drilling and grouting in one step reduces installation time.

- Good Anchoring Effect: Ensures effective load transfer and rock stabilization.

- Low Comprehensive Cost: Streamlined installation process lowers overall project costs.

- Wide Application Range: Suitable for a variety of geological conditions and project requirements.

- High Safety Performance: Reliable and robust anchoring minimizes risk in critical applications.

Seam Rock Bolts

Seam rock bolts involve pushing a thin-walled steel pipe with longitudinal slits into a hole smaller than its outer diameter. The steel pipe then generates radial pressure against the hole wall, providing resistance and anchoring.

Flower Tube Grouting Rock Bolts

Flower tube grouting rock bolts use steel pipes with small holes arranged on the pipe wall as the rod body. Grout is injected through these holes into the surrounding rock, providing a robust bond and enhanced anchoring.

Expandable Rock Bolts (Swellex)

Expandable rock bolts, often known by the brand name Swellex, are made from thin-walled steel pipes with a special-shaped cavity. These bolts are inserted into a slightly larger hole and expanded by injecting water at high pressure, generating frictional resistance against the hole wall for anchoring.

Classification by Length of Support

Rock bolts can also be classified based on their intended service life and the duration of support they provide:

Permanent Rock Bolts

Permanent rock bolts are designed to last the entire lifespan of the main project. They maintain stable performance and quality standards throughout the project's operational period and can be maintained or replaced as necessary.

Temporary Rock Bolts

Temporary rock bolts are used during specific stages of a project or only for the construction phase. They do not meet the same longevity standards as permanent bolts and are generally not considered under normal operating conditions.

Emphasis on Self-Drilling Rock Bolts

Self-drilling rock bolts have gained popularity in the market due to their ease of construction and effective anchoring. These bolts are particularly beneficial in complex geological conditions where traditional drilling and grouting methods may be challenging. The self-drilling system simplifies the installation process, making it an ideal choice for various applications:

- Slope Stabilization: Provides reliable support for unstable slopes, preventing landslides and erosion.

- Foundation Pit Support: Ensures the stability of deep excavation sites, protecting adjacent structures and workers.

- Tunnel Construction: Facilitates the safe and efficient creation of underground passages.

- Pile Foundation Support: Enhances the load-bearing capacity of pile foundations in soft or unstable soils.

- Infrastructure Projects: Supports the foundations of transmission towers, wind towers, and other critical infrastructure.

- Building Renovation: Reinforces and stabilizes old buildings, extending their service life and safety.

Conclusion

Rock bolts are an indispensable component of underground construction and geotechnical engineering, offering essential support and stabilization for various projects. With a wide range of types and construction methods, rock bolts can be tailored to meet the specific requirements of each application. Among these, self-drilling rock bolts stand out for their efficiency, effectiveness, and versatility. As the industry continues to innovate, rock bolts will remain a critical tool in ensuring the safety and stability of underground structures and slopes.

latest news

-

- 3 Crucial Factors That Impact the Quality of Self-Drilling Hollow Bolts

- Time:2025-01-26From:This Site

- As we all know, the quality of the self-drilling hollow bolts is vital to the whole project. It determines if the project is safe for the people in future use. Then, what will affect the quality of the self-drilling hollow bolts?

- View details

-

- Self-Drilling Anchor Bolt Construction in Complex Geological Slope

- Time:2025-01-24From:This Site

- During construction, Self-drilling hollow anchor bolt integrates drilling, grouting and anchoring functions, which significantly improves drilling efficiency. And under the action of pressure pump, the grouting in the rock strata and voids is full, which ensures the grouting thickness and anchoring effect.

- View details

-

- How Does Self-drilling Rock Bolt Drill in Quicksand Geological Condition?

- Time:2025-01-19From:This Site

- This in-depth guide explores how self-drilling rock bolts function in quicksand geological conditions, covering the challenges, construction methods, and best practices for ensuring effective anchorage in unstable, fluidic soil layers.

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

.png)

- International Women's Day with Strawberry-picking

- Time:2024-03-09From:This Site

- Marked the annual observance of International Women's Day, and to commemorate this significant event, Sinorock organized a special strawberry-picking event exclusively for its female employees.

- View details

-

- Celebrate the 74th anniversary of the founding of the People's Republic of China

- Time:2023-10-01From:This Site

- On October 1st every year, we observe the annual National Day, commemorating the birth of our beloved motherland.

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

-

- SINOROCK Gears Up for UGOL ROSSII & MINING 2024 with Custom Mining Solutions

- Time:2024-05-15From:This Site

- SINOROCK is thrilled to announce its participation in the highly anticipated 32nd International Trade Fair for Mining Technology, UGOL ROSSII & MINING 2024. The event will take place at the Exhibition complex "Kuzbass Fair" in Novokuznetsk, Kemerovo region - Kuzbass, Russia, from June 4th to 7th, 2024.

- View details

Download

Download