Reinforcement mechanism of self-drilling hollow anchors

Time:2021-02-22From:sinorock View:

Self drilling hollow anchors were first used in America coal mines in 1970s and began applicated in China in 1980s. Due to its fast construction speed and good anchoring effect, it has been widely used in deep foundation support projects, and gradually replacing the traditional steel anchor bar and seamless anchor bolt. Why self-drilling hollow anchor is so popular? The reason is its reinforcement mechanism.

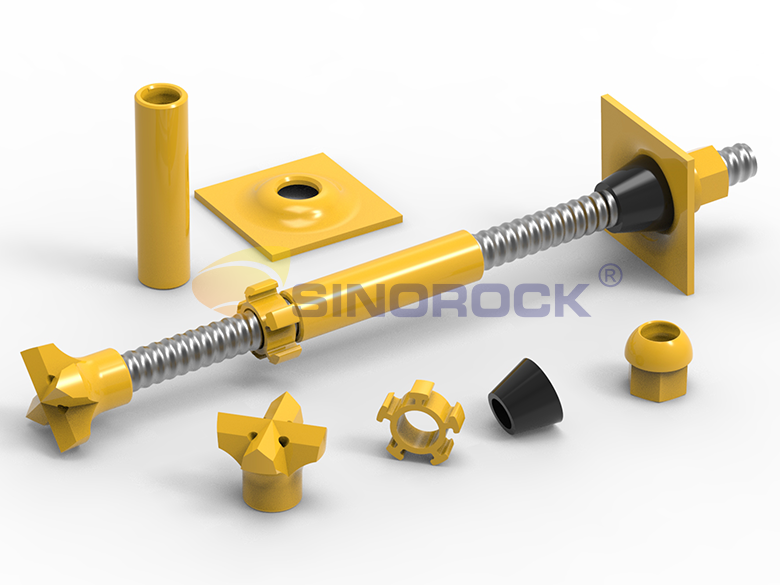

The reinforcement mechanism is as follows: Self drilling anchor bolt is mainly composed of hollow anchor bar, drill bit, plate, nut and coupling. Hollow bar's surface has continuous wave thread with international standard, which can be directly connected with the output end of drill rig to complete drilling.

The reinforcement mechanism is as follows: Self drilling anchor bolt is mainly composed of hollow anchor bar, drill bit, plate, nut and coupling. Hollow bar's surface has continuous wave thread with international standard, which can be directly connected with the output end of drill rig to complete drilling.

During drilling, hollow bar serves as a drilling rod and medium transmission channel, and it also acts as a stiffened body for geotechnical support after the completion of the project. When drilling into rock formations, compressed air or water can be injected. The air or water is used to flush out the rock fragments generated during the drilling process, and finally cement slurry is injected for anchoring. It can be grouted simultaneously when drilling into the soil layer. On the one hand, the cement slurry can drain the excess soil debris out of the hole. On the other hand, it can also consolidate the loose hole wall to prevent collapse and achieve better anchoring effect.

In a word, the integral anchoring system composed of hollow anchor bar, drill bit and coupling and connecting sleeve can be directly drilled after connecting with drill rig. And after drilling, the hollow bar can be grouted without pulling out. And after the slurry solidifies, self-drilling anchor bolt can act as stiffened body for supporting. The reinforcement mechanism of self-drilling hollow anchor is to integrate the functions of drilling, grouting and anchoring, which solves the problem of easy collapse in soft geology and realizes fast anchoring, safe and convenient efficient construction.

In a word, the integral anchoring system composed of hollow anchor bar, drill bit and coupling and connecting sleeve can be directly drilled after connecting with drill rig. And after drilling, the hollow bar can be grouted without pulling out. And after the slurry solidifies, self-drilling anchor bolt can act as stiffened body for supporting. The reinforcement mechanism of self-drilling hollow anchor is to integrate the functions of drilling, grouting and anchoring, which solves the problem of easy collapse in soft geology and realizes fast anchoring, safe and convenient efficient construction.

latest news

-

- 3 Crucial Factors That Impact the Quality of Self-Drilling Hollow Bolts

- Time:2025-01-26From:This Site

- As we all know, the quality of the self-drilling hollow bolts is vital to the whole project. It determines if the project is safe for the people in future use. Then, what will affect the quality of the self-drilling hollow bolts?

- View details

-

- Self-Drilling Anchor Bolt Construction in Complex Geological Slope

- Time:2025-01-24From:This Site

- During construction, Self-drilling hollow anchor bolt integrates drilling, grouting and anchoring functions, which significantly improves drilling efficiency. And under the action of pressure pump, the grouting in the rock strata and voids is full, which ensures the grouting thickness and anchoring effect.

- View details

-

- How Does Self-drilling Rock Bolt Drill in Quicksand Geological Condition?

- Time:2025-01-19From:This Site

- This in-depth guide explores how self-drilling rock bolts function in quicksand geological conditions, covering the challenges, construction methods, and best practices for ensuring effective anchorage in unstable, fluidic soil layers.

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

.png)

- International Women's Day with Strawberry-picking

- Time:2024-03-09From:This Site

- Marked the annual observance of International Women's Day, and to commemorate this significant event, Sinorock organized a special strawberry-picking event exclusively for its female employees.

- View details

-

- Celebrate the 74th anniversary of the founding of the People's Republic of China

- Time:2023-10-01From:This Site

- On October 1st every year, we observe the annual National Day, commemorating the birth of our beloved motherland.

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

-

- SINOROCK Gears Up for UGOL ROSSII & MINING 2024 with Custom Mining Solutions

- Time:2024-05-15From:This Site

- SINOROCK is thrilled to announce its participation in the highly anticipated 32nd International Trade Fair for Mining Technology, UGOL ROSSII & MINING 2024. The event will take place at the Exhibition complex "Kuzbass Fair" in Novokuznetsk, Kemerovo region - Kuzbass, Russia, from June 4th to 7th, 2024.

- View details

Download

Download