How to support high slopes with self drilling anchor bolts?

Time:2024-02-02From:sinorock View:

Understanding High Slopes and their Stability Challenges

A. Defining High Slopes

In the field of geotechnical engineering or engineering geology (geoengineering), the so-called "slope" generally refers to natural slopes, river bank slopes, plateau loess plateau margins, landslide deposits, as well as man-made slopes (formed by transportation roads, open-pit mines, construction sites and foundation works, etc.), and other slope forms.

It can also be broadly defined as a geologic body on the surface of the earth with a tendency to the air, mainly composed of the top of the slope, the face of the slope, the foot of the slope, and a certain range of the lower part of the slope body. There are various classifications of slopes.

According to the slope height can be divided into: low slopes, high slopes, especially high slopes; according to the cause of the slope can be divided into: artificial slopes, natural slopes; according to the material composition can be divided into soil slopes, rocky slopes, binary structure slopes and so on.

For soil slope height greater than 20m, less than 100m or rocky slope height greater than 30m, less than 100m of the slope, the slope height factors will have an important role in slope stability and impact, its slope stability analysis and protection and reinforcement engineering design should be individual or special design calculations, these slopes are called high slope.

B. Challenges to Stability in High Slopes

The common disease types of slopes are: weathering and spalling, flow of rocks and mud, falling blocks of rock, collapse, tipping, slumping, collapse, collapse, slumping, slumping, landslides, misalignment and so on 11 major categories.

1. Gravity as a Perpetual Force

High slopes are constantly subjected to the force of gravity, which contributes to the potential for soil and rock movement. The magnitude of gravitational forces intensifies with the slope's elevation, necessitating robust stability measures to counteract these effects.

2. Erosion and Environmental Influences

Erosion, triggered by rainfall and environmental factors, poses a significant threat to high slopes. The gradual loss of soil can compromise the structural integrity of the slope, leading to instability and potential failure. Understanding and mitigating erosion risks are critical aspects of high slope stability management.

3. Geological Complexity

The geological conditions of high slopes vary widely, presenting a complex challenge for engineers. Rock formations, soil types, and the presence of fault lines contribute to the diversity of conditions that must be carefully analyzed and addressed during slope stabilization efforts.

4. Potential Risks and Consequences

The consequences of instability in high slopes extend beyond project delays. Catastrophic events such as landslides and mudslides can result in severe environmental damage, threaten human safety, and incur substantial economic costs. The risks associated with slope failure underscore the need for proactive and effective stability solutions.

In navigating the intricacies of high slopes, engineers must grasp the nuanced challenges presented by gravitational forces, erosion, geological diversity, and potential consequences of instability. Addressing these factors requires a comprehensive approach that integrates advanced technologies, such as self-drilling anchor bolts, to ensure the resilience and long-term stability of high slope constructions.

Support High Slopes with Self-drilling Anchor Bolts

A. Introduction of Self-drilling Anchor Bolts

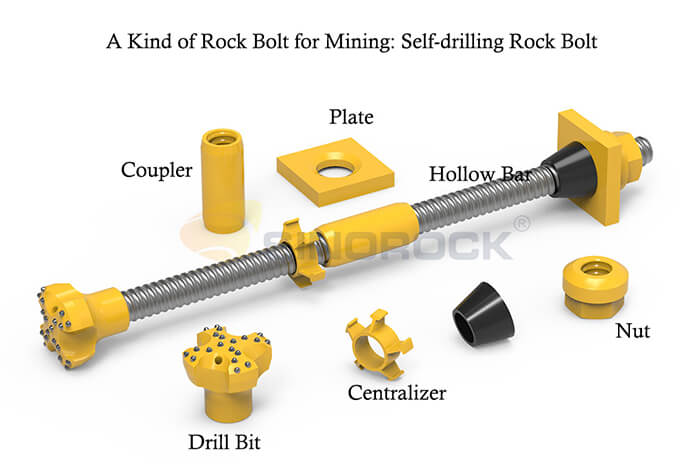

Self-drilling anchor bolt comprises a hollow anchor bar that allows for customization based on project requirements, a nut for securing the anchor, a plate for load distribution, a coupler for connecting anchor bars, a centralizer for maintaining alignment, and a drill bit for seamless penetration of various geological formations.

The self-drilling anchor bolt system distinguishes itself by offering a holistic solution to the challenges posed by complex geological conditions on high slopes. Through the incorporation of drilling, grouting, and anchoring functions within a single system, this innovation streamlines the construction process, ensuring both efficiency and effectiveness.

B. Advantages Utilizing Self-Drilling Anchor Bolts in High Slope

1. Addressing Difficult Drilling Conditions

One of the primary advantages of self-drilling anchor bolts lies in their ability to navigate challenging drilling conditions prevalent in high slopes. Complex geological formations often impede conventional drilling methods, leading to project delays. Self-drilling anchor bolts overcome this hurdle, ensuring progress and stability by combining drilling and anchoring functions.

2. Versatility and Resource Efficiency

The versatility of self-drilling anchor bolts proves instrumental in adapting to different geological formations and construction conditions. This adaptability not only minimizes the need for labor and material resources but also enhances the overall efficiency of high slope support projects. The modular nature of the system allows for cut and lengthened adjustments, ensuring a tailored approach to each unique project.

3. Comprehensive Support for Varied Slope Sizes

The application of self-drilling anchor bolts extends across a spectrum of slope sizes. For small and medium-sized slopes, the system focuses on connecting bolt heads to ensure bending rigidity, providing a comprehensive design that optimizes stability while minimizing costs. Meanwhile, for super high slopes exceeding 130 meters, strategic adjustments such as slope cutting, reinforced concrete frame beams, and the integration of PVC porous drainage pipes contribute to the system's adaptability and robust support.

Factors to Consider when Using Self-Drilling Anchor Bolts

A. Geological and Geotechnical Analysis of the Slope

1. Comprehensive Site Assessment

Undertaking a meticulous geological and geotechnical analysis of the slope is paramount before deploying self-drilling anchor bolts. This involves a thorough examination of the rock formations, soil types, fault lines, and other subsurface conditions. The data gathered serves as the foundation for an informed decision-making process in designing a customized and effective high slope support system.

2. Seismic Considerations

In regions prone to seismic activity, understanding the seismic forces at play is crucial. The geological and geotechnical analysis must incorporate seismic data to ensure that the self-drilling anchor bolts can withstand and mitigate the potential impacts of seismic events on high slopes.

B. Selection of Appropriate Anchor Bolt Materials and Specifications

1. Load-Bearing Capacity

Tailoring the selection of self-drilling anchor bolt materials to the specific load-bearing requirements of the high slope is critical. Factors such as the slope's elevation, geological conditions, and anticipated loads must be considered to ensure the chosen materials can withstand the imposed stresses and maintain long-term stability.

2. Corrosion Resistance

High slopes often expose anchor bolts to harsh environmental conditions. Selecting materials with superior corrosion resistance is essential to prevent deterioration over time. Stainless steel and other corrosion-resistant alloys are common choices to ensure the longevity of the anchor bolts in various environmental settings.

C. Monitoring and Maintenance Considerations

1. Regular Inspection Protocols

Establishing a robust monitoring system involves implementing regular inspection protocols to assess the condition of the self-drilling anchor bolts. Periodic checks allow for the early detection of potential issues, facilitating timely interventions and preventing slope instability.

2. Proactive Maintenance Strategies

Incorporating proactive maintenance strategies is imperative to extend the lifespan of the self-drilling anchor bolts. This includes addressing any signs of wear or corrosion of the bolts promptly before installation, tensioning adjustments during construction, and grout integrity checks after construction. Proactive maintenance ensures the ongoing effectiveness of the support system and mitigates the risk of unexpected failures.

Conclusion

In the process of high slope support, the treatment cost is expensive and difficult. Compared with traditional steel bars, self drilling anchor rods not only have the characteristics of light weight and high strength, but also provide supporting force after excavation of rock and soil, which can improve the strength of rock and soil, and control rock and soil deformation. Therefore, when treating high slopes, especially high slopes in loose formations, the use of self drilling anchors can greatly reduce the difficulty of treatment, reduce costs and ensure good stability of high slopes.

Sinorock, with its commitment to excellence and global expertise, emerges as a reliable partner for all rock bolt requirements. Embrace the strength and stability that Sinorock brings to your underground projects, and unlock a new level of confidence in subsurface construction. Welcome to contact: sinorock@sinorockco.com.

latest news

-

- 3 Crucial Factors That Impact the Quality of Self-Drilling Hollow Bolts

- Time:2025-01-26From:This Site

- As we all know, the quality of the self-drilling hollow bolts is vital to the whole project. It determines if the project is safe for the people in future use. Then, what will affect the quality of the self-drilling hollow bolts?

- View details

-

- Self-Drilling Anchor Bolt Construction in Complex Geological Slope

- Time:2025-01-24From:This Site

- During construction, Self-drilling hollow anchor bolt integrates drilling, grouting and anchoring functions, which significantly improves drilling efficiency. And under the action of pressure pump, the grouting in the rock strata and voids is full, which ensures the grouting thickness and anchoring effect.

- View details

-

- How Does Self-drilling Rock Bolt Drill in Quicksand Geological Condition?

- Time:2025-01-19From:This Site

- This in-depth guide explores how self-drilling rock bolts function in quicksand geological conditions, covering the challenges, construction methods, and best practices for ensuring effective anchorage in unstable, fluidic soil layers.

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

.png)

- International Women's Day with Strawberry-picking

- Time:2024-03-09From:This Site

- Marked the annual observance of International Women's Day, and to commemorate this significant event, Sinorock organized a special strawberry-picking event exclusively for its female employees.

- View details

-

- Celebrate the 74th anniversary of the founding of the People's Republic of China

- Time:2023-10-01From:This Site

- On October 1st every year, we observe the annual National Day, commemorating the birth of our beloved motherland.

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

-

- SINOROCK Gears Up for UGOL ROSSII & MINING 2024 with Custom Mining Solutions

- Time:2024-05-15From:This Site

- SINOROCK is thrilled to announce its participation in the highly anticipated 32nd International Trade Fair for Mining Technology, UGOL ROSSII & MINING 2024. The event will take place at the Exhibition complex "Kuzbass Fair" in Novokuznetsk, Kemerovo region - Kuzbass, Russia, from June 4th to 7th, 2024.

- View details

Download

Download