How to Choose A High-quality SDA Bolt System?

Time:2024-08-27From:sinorock View:

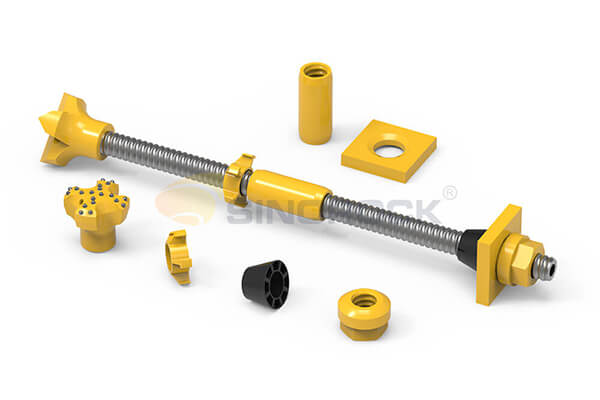

In the construction industry, especially in critical applications like tunnel support, slope stabilization, and foundation reinforcement, the self-drilling anchor (SDA) bolt system has become a crucial component. Its ability to drill, anchor, and grout simultaneously makes it indispensable in various challenging geotechnical conditions. However, selecting a high-quality SDA bolt system is not as straightforward as it might seem. Many construction professionals are still unfamiliar with the key factors that determine the quality and performance of these systems. In this expanded guide, we will explore the critical parameters to consider when choosing a self-drilling anchor bolt system, reflecting the latest industry standards and technological advancements.1. Importance of Borehole Diameter in SDA Bolt Systems

The borehole diameter is one of the most fundamental parameters when selecting a self-drilling anchor bolt. The borehole diameter directly influences the anchoring effect, which is crucial for the stability of the structure. In foundation pit support, tunnel stabilization, or slope reinforcement, a mismatch between the required and actual borehole diameter can lead to inadequate anchorage, compromising the safety and longevity of the project.

Currently, the borehole diameters offered by SDA bolt manufacturers vary significantly. Some domestic producers provide options ranging from 25mm to 200mm. However, few manufacturers can offer the versatility required to cover this entire range. A high-quality SDA bolt system should offer multiple borehole diameter options to suit various project requirements, ensuring that the chosen system can adapt to different geotechnical conditions without compromising performance.

The ability to drill larger diameters is particularly important in projects involving unstable or loose soils where a greater anchoring surface is needed. Therefore, when selecting an SDA bolt system, ensure that the product range includes diameters that meet the specific needs of your project. This consideration will help prevent potential risks and ensure that the anchoring effect is both reliable and durable.

2. Drilling Depth: A Critical Performance Indicator

Another key factor in choosing an SDA bolt system is the drilling depth capability. The depth to which the anchor can be drilled directly impacts the overall stability and effectiveness of the support system. In many construction projects, particularly those involving deep excavations or high-stress environments, achieving sufficient drilling depth is essential for the anchor to engage with more stable subsurface layers.

.jpg)

Typically, to attain the desired anchoring effect, SDA bolts need to reach depths of 15 to 20 meters, with some applications requiring even deeper installations. However, not all SDA bolts on the market can achieve these depths consistently. High-quality SDA bolt systems must be designed to drill to significant depths while maintaining structural integrity. This requires the use of superior materials and advanced drilling technology, as well as the availability of appropriate drilling rigs capable of handling the demands of deep installations.

Choosing an SDA bolt system with proven deep drilling capabilities ensures that the project’s design requirements are met. It also reduces the risk of failure, which can be costly both financially and in terms of safety. Therefore, always verify the maximum drilling depth supported by the SDA bolt system, particularly for projects where deep anchorage is a non-negotiable requirement.

3. Tensile Yield Strength: Ensuring Structural Integrity

The tensile yield strength of an SDA bolt is a critical measure of its ability to support loads without deforming or failing. In any application where SDA bolts are used, they are expected to bear substantial loads, whether from building structures, rock, or soil. Therefore, understanding the tensile yield strength of the bolt is essential for ensuring that it can meet the demands of the project.

The tensile yield strength varies significantly depending on the diameter and material of the SDA bolt. For instance, an SDA bolt with a diameter of 52mm typically offers a tensile strength of 929kN and a yield force of 730kN. In contrast, a larger 76mm diameter bolt can achieve tensile strengths as high as 1900kN with a yield force of 1500kN. The choice between these options should be based on the specific load requirements of the project.

Selecting an SDA bolt with the appropriate tensile yield strength not only ensures the structural integrity of the support system but also optimizes construction costs. Over-specifying can lead to unnecessary expenses, while under-specifying can result in insufficient support, leading to potential structural failures. Therefore, a thorough understanding of the project’s load-bearing requirements and careful selection of the appropriate SDA bolt are paramount.

4. The Sinorock Advantage in SDA Bolt Systems

Sinorock stands out as a leading manufacturer of self-drilling anchor bolts, known for its commitment to quality, innovation, and reliability. The company offers a wide range of SDA bolt systems that cater to diverse project needs, with borehole diameters ranging from 25mm to 300mm and drilling depths extending up to 40 meters. This versatility ensures that Sinorock’s products can meet the demands of various engineering projects, from shallow slope stabilization to deep foundation support.

What sets Sinorock apart is its focus on delivering high tensile yield strength across its product range, ensuring that each bolt provides the necessary load-bearing capacity for even the most challenging applications. Additionally, Sinorock’s SDA bolt systems are equipped with a variety of drill bits, allowing for customization based on the specific geotechnical conditions encountered on-site.

In an industry where the quality of materials and adherence to design specifications are critical, Sinorock’s SDA bolt systems offer a reliable solution backed by years of expertise and industry knowledge. By choosing Sinorock, construction professionals can be confident in the performance and durability of their support systems, ultimately leading to safer and more successful projects.

Conclusion

Choosing a high-quality SDA bolt system is a critical decision that can significantly impact the success of a construction project. By carefully considering factors such as borehole diameter, drilling depth, and tensile yield strength, professionals can ensure that their SDA bolt systems provide the necessary support and stability. With the rapid advancements in technology and increasing demands for safety and efficiency in construction, selecting a reliable and versatile SDA bolt system is more important than ever. Sinorock’s commitment to quality and innovation makes it a trusted partner for projects requiring top-tier self-drilling anchor bolt systems.

latest news

-

- What Are the Applications of SDA Bolts in Hydropower Stations?

- Time:2025-08-21From:This Site

- Learn how self-drilling anchor bolts enhance slope stability, tunnel support, and dam reinforcement in complex geological conditions at hydropower stations. Optimize hydropower projects with efficient, cost-effective, and eco-friendly solutions.

- View details

-

- Slope Stabilization with SDA Bolts: Benefits & Applications

- Time:2025-08-19From:This Site

- Discover how self-drilling anchor bolts (SDA bolts) provide superior slope stabilization for highways, railways, and tunnels. Learn their key benefits, installation process, and real-world applications in loose or collapsible soils.

- View details

-

- How Self-Drilling Rock Bolts Enhance Tunnel Support in Fractured Rock?

- Time:2025-08-15From:This Site

- Discover how self-drilling rock bolts enhance tunnel support in fractured rock. Learn their benefits, installation steps, and real-world applications for safe, efficient tunneling.

- View details

-

- Sinorock 2025 Quality Month | Strengthening Quality Foundations, Empowering Product Excellence

- Time:2025-08-13From:This Site

- Sinorock’s 2025 Quality Month, themed “Strengthening Quality Foundations, Empowering Product Excellence,” successfully concluded, reinforcing our commitment to superior product quality.

- View details

-

- Sinorock Safety Month 2025 | Everyone Speaks Safety, Everyone Can Respond

- Time:2025-07-03From:This Site

- Sinorock Safety Month 2025, centered on the theme "Everyone Speaks Safety, Everyone Can Respond - Spot Workplace Hazards," has wrapped up successfully!

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

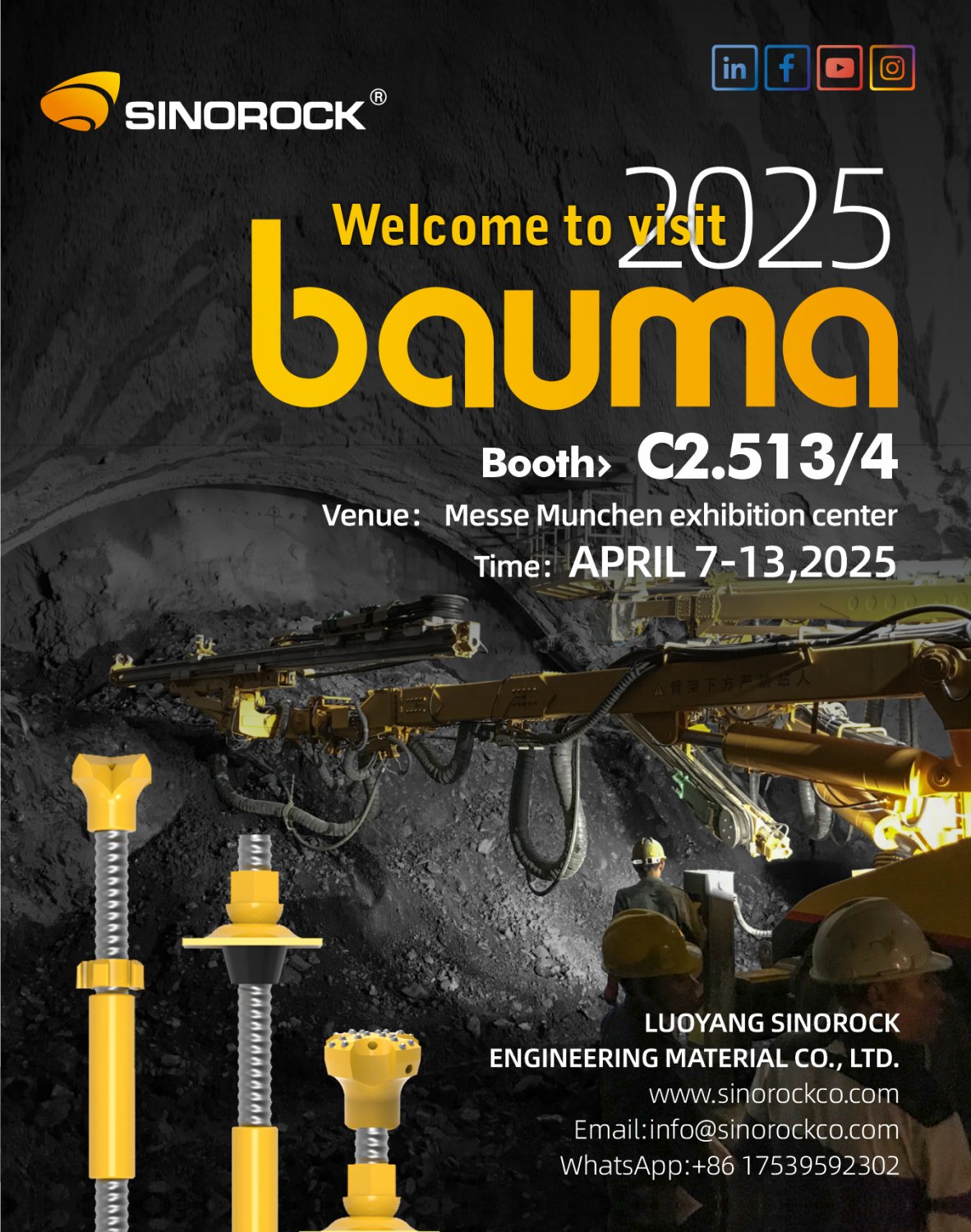

- Sinorock Invites You to Explore Proven Self-Drilling Anchor Bolt Solutions at bauma 2025

- Time:2025-03-07From:This Site

- From April 7–13, 2025, explore Sinorock’s Self-drilling anchor bolt solution at Booth C2.513/4 in Hall C2 of the Messe München Exhibition Center (Munich, Germany).

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

Download

Download