How to choose the best hollow anchor bar for corrosion protection?

Time:2025-04-04From:sinorock View: 355

In engineering applications, the biggest influence on the service life of self drilling hollow anchor bolts is stratum environment. Especially when it is used in sea area or close to the coastline, where the environment is more aggressive. Therefore, you should select hollow anchor rods for corrosion protection in aggressive environments. Next, I will introduce how to choose the best suitable anti-corrosion anchor bar in different application environments.1. Non-aggressive Environment

For non- aggressive environments, the cement grout can also protect anchor bar body from corrosion. Research shows that different stratum or application structures have corresponding requirements on the grout thickness if they want to achieve corrosion resistance. For example, when used as a compressive pile, the grout thickness should be at least 20mm; when used in soil, the thickness should be at least 20mm; when used as a tensile pile the thickness should be at least 30mm. Be sure, this is only the minimum value. At the same time, it should be noted that the crack width should not be too large, otherwise it will greatly affect the anti-corrosion performance.

2. Aggressive Environment

Aggressive environment is complex and diverse, Sinorock provides a variety of anti-corrosion anchors to meet different needs of customers.

3. Stainless steel hollow anchor bolt

Stainless steel hollow anchor bolt is made of stainless steel, with better anti-corrosion performance, and it can resist the corrosion of air and chemical media. In addition to the convenient construction characteristics of self drilling hollow anchor rods, stainless steel anchor rods also have excellent weldability, high strength and wear resistance.

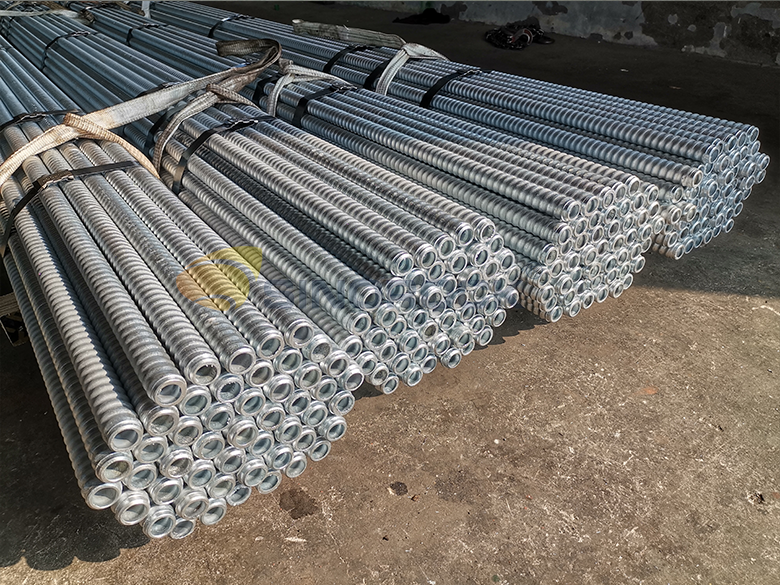

4. Hot dip galvanizing anchor bolt

.png) Galvanizing is a special precaution that can be provided to protect the hollow anchor bar against corrosion. Zinc coating applied to the steel withstands severe corrosion and represents a durable, economic form of corrosion protection. Sinorock's hot-dip galvanizing bolts meet the ISO 1461 and can be used for more than 50 years in most environments. Hot dip galvanizing anchor bolt is especially suitable for various acid, alkali mist and other corrosive environments, as well as occasions with longer service life requirements and complex environments in geotechnical engineering.

Galvanizing is a special precaution that can be provided to protect the hollow anchor bar against corrosion. Zinc coating applied to the steel withstands severe corrosion and represents a durable, economic form of corrosion protection. Sinorock's hot-dip galvanizing bolts meet the ISO 1461 and can be used for more than 50 years in most environments. Hot dip galvanizing anchor bolt is especially suitable for various acid, alkali mist and other corrosive environments, as well as occasions with longer service life requirements and complex environments in geotechnical engineering.5. Epoxy coating anchor bolt

The epoxy resin is sprayed on the bolt surface by electrostatic spraying. Sinorock epoxy coating products are mainly based on EN 13438, and the service life is not less than 30 years. Epoxy coating anchor bolt is suitable for occasions where stratum and groundwater contain sulfides and chlorides, corroded by seawater, and environments with stray currents or corrosive medium.

6. Duplex coating anchor bolt

Duplex coating is a combination of hot-dip galvanizing and epoxy coating. Firstly, product is hot-dip galvanized, and then epoxy powder is sprayed on the surface. The anchor bolt has better anti-corrosion performance and longer service life after two kinds of anti-corrosion processes. It can not only resist ordinary chemical corrosion, but also work in acidic environment and electrochemical corrosion with stray currents. Duplex coating anchor bolt is generally used in the permanent support of hydro-projects, underwater tunnels, subway tunnels and some important buildings affected by groundwater for a long time. And it is also widely used in harbors, wharfs, offshore buildings which are corroded by seawater. In most environments, the service life of duplex coating anchor bolt can reach 100 years without maintenance.

latest news

-

- How to choose the best hollow anchor bar for corrosion protection?

- Time:2025-04-04From:This Site

- In engineering applications, the biggest influence on the service life of self drilling hollow anchor bolts is stratum environment. Especially when it is used in sea area or close to the coastline, where the environment is more aggressive. Therefore, you should select hollow anchor rods for corrosion protection in aggressive environments.

- View details

-

- The Versatile Application of Self-Drilling Hollow Anchor Bars in Various Construction Projects

- Time:2025-03-30From:This Site

- Geotechnical anchoring is an important branch in the field of geotechnical engineering, and the anchoring technology adopted in geotechnical engineering can more fully exert and improve the self-strength of the geotechnical body and its own stability. As an efficient new support material in the geotechnical anchoring field, self-drilling hollow anchor has been widely used in various types of projects.

- View details

-

- How To Support The Tunnel Pass Through Cobble Layer? Self-drilling Anchor Bolt Support Method

- Time:2025-03-26From:This Site

- How to support the tunnel pass through cobble layer? Self-drilling anchor bolts can be used for support. It can solve the construction problems encountered when the tunnel passes through the cobble layer by drilling preparation, drilling and grouting, coupling the anchor bars, and pull-out test.

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

.png)

- International Women's Day with Strawberry-picking

- Time:2024-03-09From:This Site

- Marked the annual observance of International Women's Day, and to commemorate this significant event, Sinorock organized a special strawberry-picking event exclusively for its female employees.

- View details

-

- Celebrate the 74th anniversary of the founding of the People's Republic of China

- Time:2023-10-01From:This Site

- On October 1st every year, we observe the annual National Day, commemorating the birth of our beloved motherland.

- View details

-

- Sinorock Invites You to Explore Proven Self-Drilling Anchor Bolt Solutions at bauma 2025

- Time:2025-03-07From:This Site

- From April 7–13, 2025, explore Sinorock’s Self-drilling anchor bolt solution at Booth C2.513/4 in Hall C2 of the Messe München Exhibition Center (Munich, Germany).

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

Download

Download