The Versatile Application of Self-Drilling Hollow Anchor Bars in Various Construction Projects

Time:2025-03-30From:sinorock View:

Geotechnical anchoring is an important branch in the field of geotechnical engineering, and the anchoring technology adopted in geotechnical engineering can more fully exert and improve the self-strength of the geotechnical body and its own stability. As an efficient new support material in the geotechnical anchoring field, self-drilling hollow anchor has been widely used in various types of projects. These anchor bars have found their application in a wide range of construction scenarios, offering stability, safety, and cost-efficiency.Slope Engineering: Ensuring Stability on High Slopes

Slope engineering poses unique challenges, particularly when dealing with high slopes exceeding 30 meters in height or even super-high slopes exceeding 100 meters. In such scenarios, the use of self-drilling hollow anchor bars, in conjunction with full-length bonded anchor bars, is a common practice. This combined reinforcement system, along with local reinforcement techniques, plays a pivotal role in maintaining slope stability.

The inherent strength and adaptability of self-drilling hollow anchor bars make them indispensable in preventing slope failures and safeguarding critical infrastructure projects in the fields of transportation, water conservancy, hydropower, and urban geotechnical slope protection. These anchor bars effectively distribute loads and provide essential support to prevent soil erosion and slope degradation, ensuring the longevity of these essential structures.

Tunnel and Underground Works: Enhancing Safety and Stability

Tunnel and underground cavern works demand a robust support system to mitigate the risk of subsidence and sidewall displacement. The reinforcement of self-drilling hollow anchor bars, and systematic mortar anchors, with reinforced shotcrete, is now a prevalent method in ensuring the stability of surrounding rocks in these complex environments.

By effectively reducing vault subsidence and sidewall displacement, this reinforcement approach not only safeguards the structural integrity of tunnels and underground caverns but also enhances the safety of personnel and protects valuable assets during project construction. The incorporation of self-drilling hollow anchor bars into this methodology has become an industry standard due to their reliability and efficiency.

Coal Mining Project: Reinforcing the Underground

In the realm of coal mining projects, where safety and stability are paramount, self-drilling hollow anchor bars take center stage. These anchor bars, often used in conjunction with shotcrete support, are instrumental in reinforcing the surrounding rock. Remarkably, statistics reveal that approximately 5,000 kilometers of roadways are supported using this method every year.

The versatility of self-drilling hollow anchor bars shines in the challenging underground environment of coal mines, providing robust reinforcement that ensures the structural integrity of tunnels and passageways. This application significantly contributes to the safety and productivity of coal mining operations worldwide.

Foundation Pit and Foundation Engineering: Building on a Solid Base

In urban settings, where foundation pits are a common sight, self-drilling hollow anchor bars play a crucial role as support structures for pile foundations. The demanding requirements of ultimate tensile force and drilling depth necessitate the use of large-diameter self-drilling hollow anchor bars, capable of withstanding immense pressures.

These hollow anchor bars, with ultimate tensile forces that can reach up to 1900 kN, form a sturdy foundation for high-rise structures and ensure the stability of the foundation pit itself. This application not only meets the rigorous safety standards of urban construction but also enhances the durability and longevity of the built environment.

Water Conservancy and Hydropower Dam Projects: Reinforcing the Backbone of Infrastructure

Dam projects represent a unique challenge due to their need to withstand floods and provide long-lasting stability. Self-drilling hollow anchor bars offer a vital solution by fastening dam bodies to bedrock, thus strengthening or raising the dam without disrupting ongoing operations. This innovative approach significantly reduces construction costs and minimizes downtime.

Dams projects, which are subject to enormous forces, require hollow anchor bars with high tensile force values. For example, the Shiquan Dam project utilized 29 anchor bars with tensile values of 6,000 kN, showcasing the incredible strength of self-drilling hollow anchor bars. One anchor even boasted a remarkable tensile value of 8,000 kN, underlining their suitability for critical infrastructure projects.

Anti-Floating Projects: Strengthening Foundations Under Ground

In anti-floating projects, self-drilling hollow anchor bars serve as anti-floating anchor bolts, improving the utilization of soil layer strength and enhancing anchor bar durability. Various configurations of anti-floating anchor bolts, including centralized point-like arrangements, centralized line-like arrangements, and face-like uniform arrangements, offer tailored solutions to address specific construction challenges.

The integration of self-drilling hollow anchor bars into anti-floating projects not only ensures the stability of foundations but also enhances the long-term performance and safety of structures. These anchor bars act as a reliable safeguard against the potential risks associated with soil instability and foundation movement.

Conclusion: A Versatile and Indispensable Construction Solution

Self-drilling hollow anchor bars have become an integral component of contemporary construction, offering exceptional support and reinforcement in a wide range of demanding situations. Their adaptability to various terrains, ranging from steep inclinations to subterranean tunnels and coal mines, foundation pits, dams, and anti-floating projects, attests to their importance in ensuring the safety, stability, and durability of infrastructure worldwide. As construction innovations continue to evolve, self-drilling hollow anchor bars are expected to remain at the forefront of progressive engineering solutions for intricate engineering predicaments, cementing their position as the cornerstone of the construction industry's triumphs.

Sinorock's dedication to excellence translates into safer, more efficient, and cost-effective construction processes. If you have any needs or questions about self-drilling anchor systems, please feel free to contact us at sinorock@sinorockco.com.

latest news

-

- The Versatile Application of Self-Drilling Hollow Anchor Bars in Various Construction Projects

- Time:2025-03-30From:This Site

- Geotechnical anchoring is an important branch in the field of geotechnical engineering, and the anchoring technology adopted in geotechnical engineering can more fully exert and improve the self-strength of the geotechnical body and its own stability. As an efficient new support material in the geotechnical anchoring field, self-drilling hollow anchor has been widely used in various types of projects.

- View details

-

- How To Support The Tunnel Pass Through Cobble Layer? Self-drilling Anchor Bolt Support Method

- Time:2025-03-26From:This Site

- How to support the tunnel pass through cobble layer? Self-drilling anchor bolts can be used for support. It can solve the construction problems encountered when the tunnel passes through the cobble layer by drilling preparation, drilling and grouting, coupling the anchor bars, and pull-out test.

- View details

-

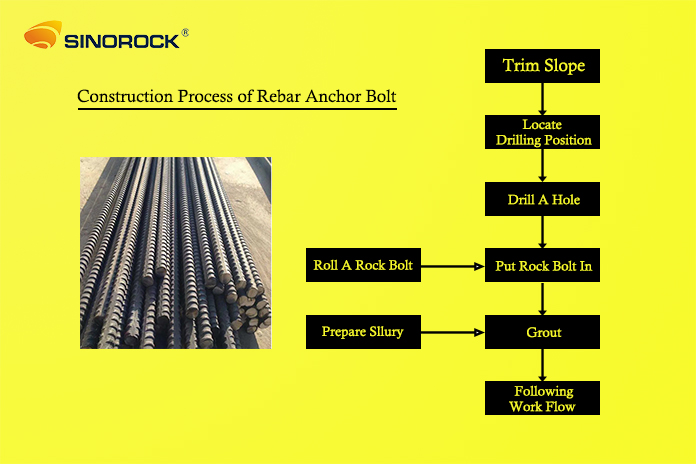

- The Comparison of Several Rock Bolts for Slope Stability

- Time:2025-03-23From:This Site

- There are various types of rock bolts used for this purpose, including rebar anchor bolts, hollow bolts, and self-drilling rock bolts. Each type of rock bolt has its unique characteristics, advantages, and disadvantages, making them suitable for different slope conditions.

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

.png)

- International Women's Day with Strawberry-picking

- Time:2024-03-09From:This Site

- Marked the annual observance of International Women's Day, and to commemorate this significant event, Sinorock organized a special strawberry-picking event exclusively for its female employees.

- View details

-

- Celebrate the 74th anniversary of the founding of the People's Republic of China

- Time:2023-10-01From:This Site

- On October 1st every year, we observe the annual National Day, commemorating the birth of our beloved motherland.

- View details

-

- Sinorock Invites You to Explore Proven Self-Drilling Anchor Bolt Solutions at bauma 2025

- Time:2025-03-07From:This Site

- From April 7–13, 2025, explore Sinorock’s Self-drilling anchor bolt solution at Booth C2.513/4 in Hall C2 of the Messe München Exhibition Center (Munich, Germany).

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

Download

Download