A Kind of Rock Bolt for Mining: Self-drilling Rock Bolt System

Time:2024-08-13From:sinorock View:

I. Introduction

Mining operations are delving deeper than ever before in pursuit of untapped underground natural resources. With this drive to access deeper deposits comes increased challenges, particularly in ensuring the safety and stability of underground environments. Rock bolts have long been a critical component in maintaining the structural integrity of mines, providing essential support in various geological conditions. Among the diverse array of rock bolts available, the self-drilling rock bolt system particularly in challenging environments where traditional methods may fall short.

II. Traditional Rock Bolts

A. Definition and Purpose

Traditional rock bolts have been the backbone of underground support systems for decades. Their primary function is to stabilize rock masses, preventing collapses and maintaining the safety of mining operations. These bolts work by transferring load from the unstable exterior to the more stable interior of the rock mass, thereby reinforcing the surrounding environment.

B. Types of Conventional Rock Bolts

Conventional rock bolts come in various forms, including expansion shell bolts, split set bolts, and fiber-reinforced plastic (FRP) bolts. Each type has its specific applications and advantages, with expansion shell bolts being widely used due to their reliability and ease of installation, and FRP bolts being favored in environments requiring non-corrosive materials.

C. Limitations of Traditional Systems

While effective, traditional rock bolt systems have limitations. These include the need for pre-drilled holes, which can be time-consuming and challenging in certain geological conditions. Additionally, traditional bolts may not perform well in fractured or loose rock, where maintaining hole stability during installation is difficult. These challenges have driven the development of more advanced systems like the self-drilling rock bolt.

III. Self-drilling Rock Bolt System

A. Definition and Concept

The self-drilling rock bolt system is an innovative solution designed to overcome the limitations of traditional rock bolts. It combines drilling, grouting, and anchoring into a single operation, making it particularly suitable for unstable ground conditions where conventional methods might fail.

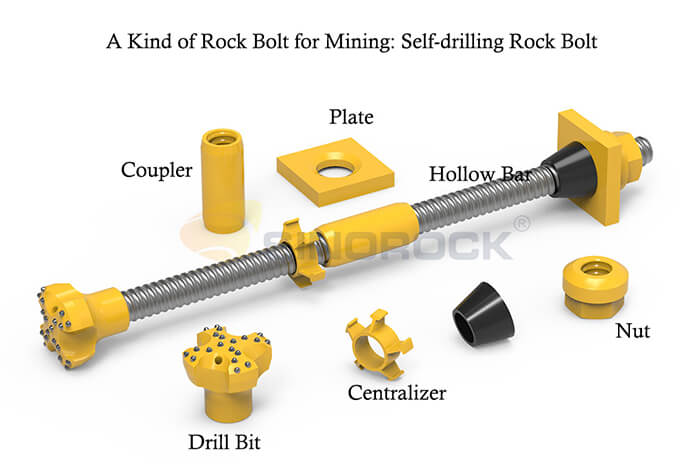

B. Key Components

The system comprises several critical components:

Sacrificial Drill Bit: This bit, which varies in type (EX, EXX, EY, EYY), is used to drill through rock and soil and is left in place after installation.

Steel Hollow Bar: Serving as both the drill rod and the anchor, the hollow bar allows for grouting through its core.

Coupler: Used to extend the hollow bar, enabling deeper installations.

Plate and Nut: These components secure the bolt to the rock face.

Centralizer: Ensures that the hollow bar remains centered within the drill hole, optimizing the grouting process and enhancing stability.

C. Working Principle

The self-drilling rock bolt system operates by combining multiple functions into one seamless process. As the drill bit penetrates the rock, the hollow bar follows, allowing for simultaneous grouting. This grouting process can be performed under high pressure, ensuring that the cement slurry fills all cracks and voids in the surrounding rock, effectively consolidating the rock mass. Once the grouting is complete, the system provides immediate support, making it particularly effective in unstable or challenging ground conditions.

IV. Advantages of Self-drilling Rock Bolt Systems

A. Time Efficiency

One of the most significant advantages of the self-drilling rock bolt system is its ability to combine drilling, grouting, and anchoring in a single step. This integration dramatically reduces installation time, making it possible to stabilize large areas of rock more quickly than with traditional methods.

B. Improved Safety

By providing immediate support as the bolt is installed, self-drilling systems enhance the safety of underground operations. The ability to stabilize fractured or loose rock quickly reduces the risk of collapses, protecting workers and equipment.

C. Reduced Equipment Requirements

Self-drilling rock bolt systems eliminate the need for separate drilling and grouting equipment, simplifying the logistics of underground support. This reduction in equipment not only lowers costs but also makes it easier to operate in confined spaces where traditional equipment might not fit.

D. Enhanced Performance in Difficult Ground Conditions

In fractured, loose, or unstable ground, where traditional rock bolts may struggle, self-drilling systems excel. The ability to grout under pressure ensures that even the most challenging rock formations can be effectively consolidated, providing reliable support in conditions that would otherwise be difficult to manage.

V. Installation Process

A. Site Preparation

Before installation, it is crucial to assess the site and prepare the drilling area. This includes evaluating the geological conditions and determining the appropriate bolt length and diameter for the specific application.

B. Drilling and Simultaneous Bolt Insertion

The installation begins with the drilling process, where the sacrificial drill bit penetrates the rock. As the drill progresses, the hollow bar is simultaneously inserted into the hole, ensuring a secure fit.

C. Grouting and Anchoring

Once the bolt is in place, grout is injected through the hollow bar, filling the surrounding voids and cracks. This grouting process not only anchors the bolt but also reinforces the surrounding rock mass.

VI. Applications in Mining

A. Underground Mining

Self-drilling rock bolt systems are widely used in underground mining to stabilize tunnels, shafts, and other excavations. Their ability to provide immediate support makes them ideal for securing unstable ground in deep mining operations.

B. Tunneling

In tunneling projects, self-drilling bolts are used to reinforce the tunnel walls and roof, preventing collapses and ensuring the safety of workers and equipment.

C. Slope Stabilization

Self-drilling bolts are also employed in slope stabilization projects, where they help to prevent landslides and erosion by anchoring the soil and rock in place.

D. Temporary and Permanent Support

Whether for temporary reinforcement during construction or for permanent support in long-term operations, self-drilling rock bolt systems offer a versatile solution that can be adapted to various needs.

VII. Comparison with Traditional Rock Bolts

A. Installation Speed

Self-drilling rock bolts significantly outpace traditional systems in terms of installation speed, thanks to their integrated drilling and grouting process. This speed is particularly beneficial in time-sensitive projects where delays can have costly consequences.

B. Cost-effectiveness

While the initial cost of self-drilling bolts may be higher than traditional bolts, their efficiency and reduced equipment requirements often result in lower overall project costs. The ability to complete installations more quickly also translates to labor savings.

C. Versatility

Self-drilling bolts can be used in a wide range of geological conditions, from hard rock to loose soil, making them more versatile than many traditional systems. Their ability to be extended or cut to fit specific needs further enhances their adaptability.

D. Performance in Various Rock Conditions

In challenging ground conditions, self-drilling bolts outperform traditional systems by providing more reliable and consistent support. Their ability to grout under pressure ensures that even fractured or unstable rock can be effectively stabilized.

VIII. Challenges and Limitations

A. Initial Cost Considerations

One of the primary challenges associated with self-drilling rock bolts is their higher initial cost compared to traditional bolts. However, this cost is often offset by the time and labor savings achieved during installation.

B. Specialized Training Requirements

The installation of self-drilling rock bolt systems requires specialized training to ensure proper use. This training may involve a learning curve for workers accustomed to traditional systems.

C. Potential Limitations in Certain Geological Conditions

While self-drilling bolts are highly versatile, they may not be suitable for all geological conditions. In some cases, particularly in extremely hard rock, alternative support systems may be more effective.

IX. Conclusion

The self-drilling rock bolt system represents a significant advancement in the field of underground mining support. Its ability to combine drilling, grouting, and anchoring in a single operation makes it an efficient and effective solution for stabilizing even the most challenging ground conditions. As the mining industry continues to evolve, the adoption of self-drilling systems is likely to increase, driven by their potential to enhance safety, reduce costs, and improve overall project efficiency.

In the competitive landscape of rock bolt systems, Sinorock has emerged as a leader, offering a range of self-drilling rock bolts that stand out for their quality, reliability, and performance. Sinorock's self-drilling rock bolts are designed to meet the demands of modern mining operations, providing a robust solution that can be tailored to a wide range of geological conditions. With a commitment to innovation and customer satisfaction, Sinorock continues to set the standard for excellence in underground support systems, ensuring that their products remain at the forefront of the industry.

latest news

-

- What Are the Applications of SDA Bolts in Hydropower Stations?

- Time:2025-08-21From:This Site

- Learn how self-drilling anchor bolts enhance slope stability, tunnel support, and dam reinforcement in complex geological conditions at hydropower stations. Optimize hydropower projects with efficient, cost-effective, and eco-friendly solutions.

- View details

-

- Slope Stabilization with SDA Bolts: Benefits & Applications

- Time:2025-08-19From:This Site

- Discover how self-drilling anchor bolts (SDA bolts) provide superior slope stabilization for highways, railways, and tunnels. Learn their key benefits, installation process, and real-world applications in loose or collapsible soils.

- View details

-

- How Self-Drilling Rock Bolts Enhance Tunnel Support in Fractured Rock?

- Time:2025-08-15From:This Site

- Discover how self-drilling rock bolts enhance tunnel support in fractured rock. Learn their benefits, installation steps, and real-world applications for safe, efficient tunneling.

- View details

-

- Sinorock 2025 Quality Month | Strengthening Quality Foundations, Empowering Product Excellence

- Time:2025-08-13From:This Site

- Sinorock’s 2025 Quality Month, themed “Strengthening Quality Foundations, Empowering Product Excellence,” successfully concluded, reinforcing our commitment to superior product quality.

- View details

-

- Sinorock Safety Month 2025 | Everyone Speaks Safety, Everyone Can Respond

- Time:2025-07-03From:This Site

- Sinorock Safety Month 2025, centered on the theme "Everyone Speaks Safety, Everyone Can Respond - Spot Workplace Hazards," has wrapped up successfully!

- View details

-

- Quality Control: the Vital Factor of A SDA Bolt Factory

- Time:2025-01-09From:This Site

- Sinorock’s comprehensive quality control system, from supplier management to outgoing inspections, ensuring the highest standards for self-drilling anchor bolts in construction.

- View details

-

- Sinorock Invites You to Explore Proven Self-Drilling Anchor Bolt Solutions at bauma 2025

- Time:2025-03-07From:This Site

- From April 7–13, 2025, explore Sinorock’s Self-drilling anchor bolt solution at Booth C2.513/4 in Hall C2 of the Messe München Exhibition Center (Munich, Germany).

- View details

-

.jpg)

- SINOROCK to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- Time:2024-08-10From:This Site

- Sinorock to Attend EXPOMINA PERÚ 2024 in Lima, Peru

- View details

-

.jpg)

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- Time:2024-08-08From:This Site

- SINOROCK to Participate in MINING AND METALS CENTRAL ASIA 2024

- View details

Download

Download